Author: Daniel Group

November 5th, 2025

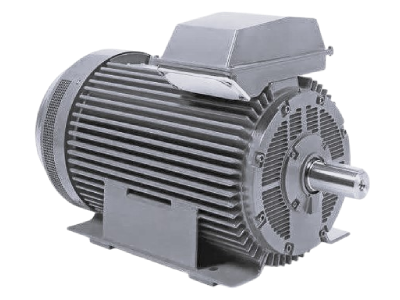

Electric motors form the heartbeat of modern industry—powering everything from conveyor systems and water pumps to HVAC units, marine propulsion systems, and oilfield machinery. They convert electrical energy into mechanical motion with unmatched efficiency, reliability, and versatility. Understanding the types of electric motors is essential for engineers, maintenance teams, and procurement managers who rely on continuous uptime and precision-driven performance.

In this comprehensive guide, we’ll examine what are the types of electric motors, their core working principles, diverse industrial applications, and the crucial maintenance and repair practices that enhance their operational life. Whether you manage a high-voltage motor in a refinery or a compact drive in a manufacturing plant, the insights shared here will help you make informed, long-term decisions about motor selection and upkeep.

Electric motors are the driving force behind most industrial systems. From powering pumps, compressors, and conveyors to controlling HVAC units and marine propulsion, motors deliver the mechanical energy needed for continuous operations. However, not all motors are designed for the same function. Each configuration—whether AC or DC—serves specific load characteristics, speed control requirements, and operating environments.

Understanding all types of electric motors helps engineers and maintenance professionals make informed decisions that:

Selecting the right motor type is not just about capacity—it’s about compatibility with the working environment, mechanical load, and control system. For instance, high-humidity or explosive environments demand motors with special insulation and protection standards, while high-speed machinery requires precise dynamic balancing to prevent vibration and wear.

In critical industries such as oil & gas, utilities, marine, and manufacturing, even small mismatches between the motor design and operational load can result in overheating, performance losses, or premature failure. Knowing different types of electric motors and their unique characteristics is therefore key to maintaining safety, reliability, and cost-effectiveness.

At the core of every electric motor lies one unifying concept—electromagnetic induction. This principle enables the conversion of electrical energy into mechanical energy through the interaction between electric current and magnetic fields.

When a current passes through a conductor (such as a copper coil) placed within a magnetic field, it experiences a force that generates rotational motion. This motion, measured as torque and speed, drives the connected mechanical load—whether it’s a pump impeller, fan blade, or gearbox shaft.

The performance and efficiency of types of electric motors depend on several key factors:

Although both AC and DC electric motors operate using the same electromagnetic principle, their designs differ significantly:

Modern industrial systems often employ types of AC electric motors with advanced control mechanisms that allow for smoother startup, reduced inrush current, and optimized power consumption. Understanding how each design responds to different conditions helps engineers select motors that deliver consistent performance even under demanding loads.

When exploring what are the types of electric motors, it’s essential to understand how each category functions and where it fits in real-world operations. Broadly, all types of electric motors fall under two main classifications: AC (Alternating Current) and DC (Direct Current) motors. Each is designed with unique internal configurations and control mechanisms that make them suitable for specific performance requirements, environmental conditions, and maintenance considerations.

AC electric motors dominate the industrial landscape for their combination of reliability, high efficiency, and minimal upkeep. These motors operate using alternating current, converting electrical energy into mechanical motion through electromagnetic induction. The types of AC electric motors can be divided into four main subtypes:

Also known as asynchronous motors, induction motors are the most widely used in industries worldwide. Their rotor current is induced rather than supplied directly, making them simple, robust, and cost-effective.

Synchronous motors maintain a constant speed regardless of load, making them ideal for precision-driven processes.

These motors are primarily used in domestic and light commercial equipment where three-phase supply isn’t available.

Three-phase motors are the backbone of heavy industries, capable of handling large mechanical loads with high torque and efficiency.

DC electric motors are valued for their precise speed and torque control, making them indispensable in applications requiring variable motion or quick reversals. While less common in large-scale industries today due to maintenance demands, DC motors remain vital in specialized equipment and mobile machinery. The different types of electric motors under this category include:

In this type, the field winding is connected in series with the armature, resulting in high starting torque.

With field windings connected parallel to the armature, shunt motors offer stable speed under varying loads.

These combine both series and shunt field windings, providing a balance between high starting torque and steady-speed control.

In every industrial ecosystem, different types of electric motors serve specific mechanical and operational purposes. Understanding where and why each motor type performs best helps engineers select efficient solutions and plan maintenance schedules that align with production demands.

AC induction motors dominate the HVAC sector, driving fans, compressors, and blowers. Their high efficiency, reliability, and low maintenance make them ideal for systems that run continuously in temperature-controlled environments. In large commercial and industrial buildings, variable frequency drives (VFDs) paired with these motors allow precise airflow control and reduced energy consumption.

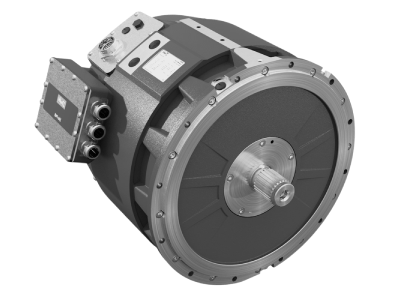

Marine propulsion systems depend on synchronous and three-phase AC motors for stable, vibration-free operation. These motors power deck machinery, hydraulic pumps, and ventilation systems aboard ships and offshore platforms. Their corrosion-resistant design, combined with Daniel Group’s expertise in marine motor repair, ensures consistent performance even in harsh saltwater environments.

In heavy industries like steel, cement, or packaging, three-phase induction motors are the backbone of continuous production. They drive conveyor systems, pumps, crushers, and compressors—offering excellent torque control and energy efficiency. Their robust construction allows them to operate under high mechanical stress, while advanced predictive maintenance tools help detect faults before breakdowns occur.

In refineries, drilling rigs, and processing plants, explosion-proof AC electric motors are essential. These motors are engineered to prevent ignition in flammable atmospheres while maintaining peak reliability under extreme temperature and pressure conditions. From submersible pumps to agitators, they support mission-critical operations where downtime translates to significant losses.

Renewable and Sustainable Energy Systems

DC motors are integral to solar tracking systems and small wind turbines, where variable speed control is crucial. They adjust solar panel angles for maximum sun exposure or modulate turbine blades based on wind speed. Lightweight, efficient, and responsive, DC motors bridge traditional and modern energy solutions by offering flexibility in hybrid renewable systems.

Power generation plants, water treatment facilities, and municipal pumping stations rely on synchronous and induction motors for steady performance under variable loads. These motors deliver continuous torque, withstand fluctuating voltages, and are designed for long service life, supporting essential public and industrial operations.

By understanding all types of electric motors, engineers can align motor specifications with environmental conditions, mechanical loads, and operational goals—enhancing productivity, reliability, and overall system efficiency.

Every electric motor, regardless of type or application, requires periodic care to ensure consistent performance and avoid costly failures. Proactive maintenance not only extends the lifespan of different types of electric motors but also improves energy efficiency and operational safety.

Bearings are critical to smooth motor operation. Over time, they can degrade due to contamination, misalignment, or improper lubrication. Regular vibration analysis helps identify wear patterns early, allowing timely replacement. Using high-grade bearings and precision alignment tools minimizes friction, noise, and unplanned shutdowns.

Insulation breakdown is one of the leading causes of motor failure. Periodic insulation resistance tests detect early deterioration in stator windings caused by heat, moisture, or chemical exposure.

Dynamic Balancing

Unbalanced rotors lead to excessive vibration, reduced bearing life, and structural fatigue. Dynamic balancing ensures uniform weight distribution and smoother operation. This service is particularly vital for AC induction motors used in high-speed or vibration-sensitive machinery. Precision balancing extends motor lifespan and improves efficiency.

Proper lubrication prevents metal-to-metal contact and heat buildup in both bearings and gear systems. Scheduled re-lubrication, along with cleaning of cooling fans and air passages, helps maintain thermal stability. In marine and desert environments, where dust and humidity levels are high, customized lubrication schedules are essential.

Motors operating in dusty or corrosive environments—like cement plants or offshore rigs—require regular cleaning to remove deposits from stator vents and cooling fins. Re-greasing ensures smooth bearing performance under load, especially in types of AC electric motors subjected to continuous operation.

Periodic no-load and full-load tests, along with shaft alignment verification, help maintain efficiency and prevent stress on couplings or driven equipment. Electrical testing also helps detect phase imbalances, overcurrent issues, or deviations in power factor that could lead to premature failure.

Routine inspections conducted by qualified professionals help detect minor issues before they escalate into costly downtime. When handled systematically, preventive maintenance transforms different types of electric motors into reliable, long-term assets rather than recurring repair costs.

Even with meticulous preventive care, different types of electric motors will eventually require professional repair or complete overhaul due to wear, insulation degradation, or environmental exposure. A systematic, workshop-based approach ensures that each motor is restored to OEM-level performance and reliability.

When windings burn out or insulation fails, motor rewinding becomes essential to restore performance and efficiency. Skilled technicians replace damaged coils with high-grade copper windings, ensuring superior conductivity, minimal power loss, and long-term reliability. Each motor rewinding process follows stringent insulation class standards (Class F or H), depending on the motor’s application and operating temperature. After rewinding, comprehensive surge and resistance testing is conducted to verify electrical integrity before reassembly—ensuring the motor performs at OEM-level precision.

Rotor and stator cores form the mechanical heart of all types of electric motors. Over time, they can develop imbalances, eccentric wear, or core losses. Precision machining, alignment, and varnish curing restore mechanical symmetry and magnetic efficiency. The stator slots are re-insulated and baked under controlled temperature to reinforce dielectric strength, ensuring long-term stability.

Persistent vibration often signals deeper issues such as misalignment, unbalanced rotors, or bearing defects. Through vibration analysis and spectrum diagnostics, engineers identify both mechanical and electrical sources of imbalance early. Corrective measures—such as dynamic balancing or bearing realignment—are applied to prevent cascading damage and operational downtime.

Every overhauled motor undergoes dynamic balancing to eliminate rotational vibration. Using advanced balancing machines, technicians simulate full-speed operation to achieve optimal weight distribution across rotor assemblies. This process enhances efficiency, reduces bearing stress, and ensures smooth operation across load variations.

In regions like the UAE, where motors operate in high-temperature, humid, or dusty conditions, upgrading insulation systems is vital. Epoxy-resin varnishes, tropicalized coatings, and improved ventilation designs extend the operational life of both AC and DC electric motors. Thermal sensors, overload relays, and moisture-resistant insulation are often integrated during overhaul for added protection.

A complete repair process includes electrical testing, mechanical inspection, and condition monitoring. Each motor is restored, balanced, and load-tested to verify torque, current draw, and efficiency before deployment. This ensures OEM-level precision, long-term durability, and consistent performance under operational conditions.

Choosing from all types of electric motors requires more than comparing power ratings—it involves matching the motor’s performance characteristics to its operational environment, duty cycle, and control requirements. The following factors are key to an effective selection process:

Load Type and Torque Demand

Determine whether the system operates under constant, variable, or intermittent loads. For steady loads, induction motors are ideal, while DC or synchronous motors are better suited for variable-speed or torque-sensitive applications.

Operating Environment

Motors used in marine, desert, or hazardous areas need appropriate enclosures—such as IP55-rated or explosion-proof housings. In humid or corrosive environments, sealed bearings and anti-condensation heaters are critical for reliable operation.

Speed and Control Requirements

When precise speed regulation is essential—such as in conveyor systems or mixers—types of AC electric motors combined with variable frequency drives (VFDs) deliver smooth and accurate control. DC motors are still favored in systems requiring fine speed variation at low power levels.

Power Source and Voltage Supply

The available power supply influences motor choice. Single-phase motors suit small installations or light-duty applications, while three-phase motors offer higher efficiency and torque for industrial equipment.

Serviceability and Spare Part Availability

Ease of maintenance and access to spare parts significantly affect lifecycle cost. Selecting motors with standard frame sizes, modular components, and readily available spares ensures faster turnaround during service or repairs.

By considering these criteria, engineers and decision-makers can identify the most suitable type of electric motor for their specific needs—balancing performance, efficiency, and long-term reliability.

In modern industries, maintenance is not just reactive—it is data-driven. Predictive and preventive maintenance strategies work together to reduce failure risks, optimize energy use, and extend the lifespan of different types of electric motors.

Predictive Maintenance Technologies

Tools such as vibration monitoring, infrared thermography, and electrical signature analysis allow early detection of issues before failure occurs. For instance, increased vibration levels may indicate bearing wear, while infrared scans can reveal overheating or insulation breakdowns.

Preventive Maintenance Practices

Regular checks—such as shaft alignment, insulation resistance testing, and bearing lubrication—form the foundation of preventive care. Scheduling these activities based on operating hours rather than fixed intervals enhances precision and efficiency.

Integrated Maintenance Strategies

Combining predictive insights with routine preventive measures helps industries plan maintenance proactively, reducing unexpected shutdowns. This integrated approach can extend the lifespan of all types of electric motors by several years, improving equipment reliability and operational uptime.

Understanding the different types of electric motors and their maintenance requirements is fundamental to achieving long-term industrial reliability. The right combination of motor selection, predictive care, and skilled repair minimizes energy losses, enhances safety, and extends equipment lifespan.

Whether your operations rely on AC or DC electric motors, consistent performance depends on proper installation, routine inspection, and timely servicing. Partnering with a trusted electromechanical specialist ensures that every component—rotor, stator, and winding—operates at peak efficiency, even in demanding environments.

Looking to optimize your electric motor performance or schedule a detailed maintenance inspection?

Get in touch with our expert team today to discuss tailored solutions for motor repair, rewinding, or predictive maintenance—ensuring maximum uptime, reliability, and cost efficiency for your operations.