Dynamic Balancing Services

Dynamic Balancing Services in UAE – Precision, Efficiency & Vibration Reduction

Enhance the efficiency, lifespan, and performance of rotating machinery with expert dynamic balancing solutions in the UAE.

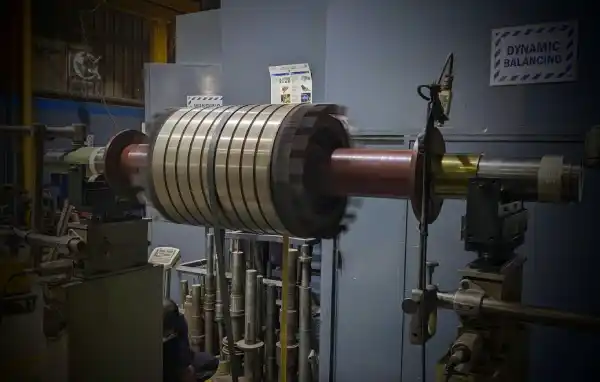

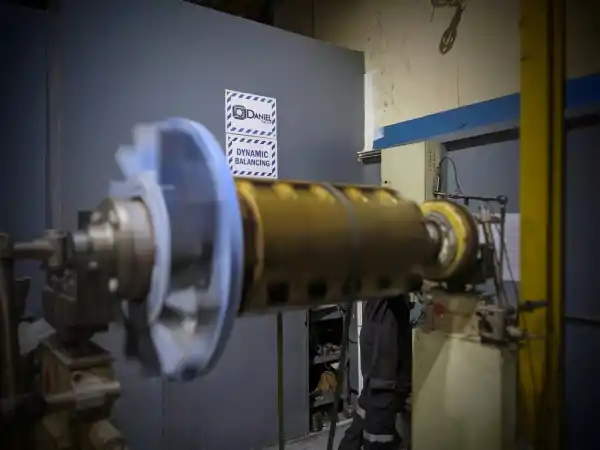

Dynamic Balancing of rotating equipment’s at Daniel Group

Dynamic balancing at Daniel Group is the process of balancing a rotating component (such as an electric motor rotor, cooling tower fan, or pump impeller) by correcting any uneven distribution of mass while it is in motion. This ensures that the component rotates smoothly without causing vibrations, noise, or excessive wear.

In an unbalanced rotating system, centrifugal forces create oscillations, leading to mechanical stress and potential failure. Dynamic balancing involves identifying these imbalances using specialized equipment, such as balancing machines or vibration analysers, and correcting them by adding or removing material (e.g., adding counterweights or machining away excess material).

Static Balancing: Corrects imbalance in a stationary rotor. The component is balanced on rollers to ensure it doesn’t tip to one side. This is an outdated process and predominately performed prior to dynamic balancing for excessively new unbalanced rotating equipment’s

Dynamic Balancing: Performed while the rotor is spinning at operational speeds, which is necessary for components that experience imbalance due to centrifugal forces.

International Standard ISO 1940 is a widely accepted reference for selecting rigid rotor balance quality. For rotors in a constant (rigid) state, only the resultant unbalance and the resultant moment unbalance (resultant couple unbalance) are of interest, both together often expressed as dynamic unbalance.

ISO 1940 gives specifications for rotors in a constant (rigid) state. It specifies

- balance tolerances,

- the necessary number of correction planes, and

- methods for verifying the residual unbalance.

Dynamic balancing is classified into different balance quality grades based on ISO 1940 standards. These grades determine the allowable residual imbalance in rotating machinery and are critical for ensuring optimal performance and longevity.

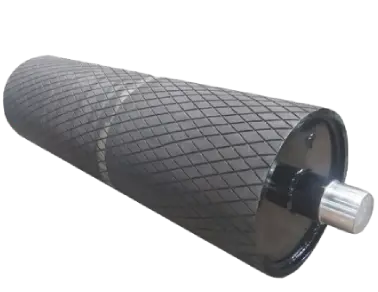

- G16 – G40: Suitable for crude industrial applications like unbalanced pulleys, conveyor rollers, and large fans.

- G6.3: Standard for electric motors, pumps, generators, and turbines used in industrial applications.

- G2.5: Precision balancing for high-speed rotating equipment, including turbochargers, machine tool spindles, and high-performance fans.

- G1.0: Required for aerospace components, gyroscopes, and precision measuring instruments where ultra-low vibration is essential.

- G0.4 – G0.1: Extreme precision levels for medical devices, optical instruments, and micro-mechanical components.

Choosing the correct dynamic balancing grade ensures longer equipment life, reduced vibration, and energy efficiency in Dubai, Abu Dhabi, and Sharjah industries.

Dynamic balancing at Daniel Group is performed in either single-plane or two-plane configurations, depending on the size, speed, and operational requirements of the rotating component. Selecting the right balancing method is crucial for minimizing vibration, extending equipment lifespan, and improving efficiency in industries across Dubai, Abu Dhabi, and Sharjah.

Single-Plane Balancing

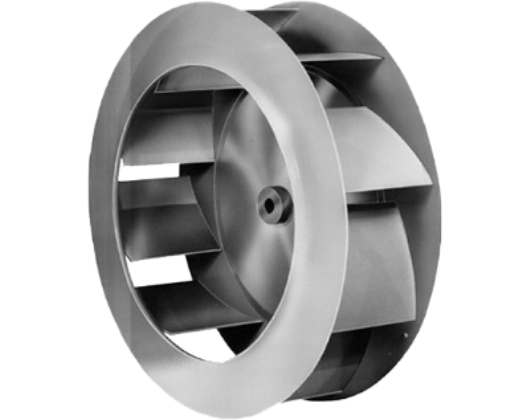

- Used for narrow or disc-shaped rotors, such as flywheels, pulleys, and fans.

- Corrects imbalance in a single correction plane, typically at the rotor’s centre.

- Ideal for components where imbalance forces do not change along the rotor’s length.

Two-Plane Balancing

- Required for longer rotors, such as turbines, fans, large shafts, motor rotors, blowers.

- Corrects imbalance in two planes, accounting for both mass distribution and rotational forces.

- Essential for high accuracy industrial machinery, reducing wear, vibration, and operational risks.

Dynamic balancing at Daniel Group is the process of balancing a rotating component (such as an electric motor rotor, cooling tower fan, or pump impeller) by correcting any uneven distribution of mass while it is in motion. This ensures that the component rotates smoothly without causing vibrations, noise, or excessive wear.

In an unbalanced rotating system, centrifugal forces create oscillations, leading to mechanical stress and potential failure. Dynamic balancing involves identifying these imbalances using specialized equipment, such as balancing machines or vibration analysers, and correcting them by adding or removing material (e.g., adding counterweights or machining away excess material).

Static Balancing: Corrects imbalance in a stationary rotor. The component is balanced on rollers to ensure it doesn’t tip to one side. This is an outdated process and predominately performed prior to dynamic balancing for excessively new unbalanced rotating equipment’s

Dynamic Balancing: Performed while the rotor is spinning at operational speeds, which is necessary for components that experience imbalance due to centrifugal forces.

International Standard ISO 1940 is a widely accepted reference for selecting rigid rotor balance quality. For rotors in a constant (rigid) state, only the resultant unbalance and the resultant moment unbalance (resultant couple unbalance) are of interest, both together often expressed as dynamic unbalance.

ISO 1940 gives specifications for rotors in a constant (rigid) state. It specifies

- balance tolerances,

- the necessary number of correction planes, and

- methods for verifying the residual unbalance.

Dynamic balancing is classified into different balance quality grades based on ISO 1940 standards. These grades determine the allowable residual imbalance in rotating machinery and are critical for ensuring optimal performance and longevity.

- G16 – G40: Suitable for crude industrial applications like unbalanced pulleys, conveyor rollers, and large fans.

- G6.3: Standard for electric motors, pumps, generators, and turbines used in industrial applications.

- G2.5: Precision balancing for high-speed rotating equipment, including turbochargers, machine tool spindles, and high-performance fans.

- G1.0: Required for aerospace components, gyroscopes, and precision measuring instruments where ultra-low vibration is essential.

- G0.4 – G0.1: Extreme precision levels for medical devices, optical instruments, and micro-mechanical components.

Choosing the correct dynamic balancing grade ensures longer equipment life, reduced vibration, and energy efficiency in Dubai, Abu Dhabi, and Sharjah industries.

Dynamic balancing at Daniel Group is performed in either single-plane or two-plane configurations, depending on the size, speed, and operational requirements of the rotating component. Selecting the right balancing method is crucial for minimizing vibration, extending equipment lifespan, and improving efficiency in industries across Dubai, Abu Dhabi, and Sharjah.

Single-Plane Balancing

- Used for narrow or disc-shaped rotors, such as flywheels, pulleys, and fans.

- Corrects imbalance in a single correction plane, typically at the rotor’s centre.

- Ideal for components where imbalance forces do not change along the rotor’s length.

Two-Plane Balancing

- Required for longer rotors, such as turbines, fans, large shafts, motor rotors, blowers.

- Corrects imbalance in two planes, accounting for both mass distribution and rotational forces.

- Essential for high accuracy industrial machinery, reducing wear, vibration, and operational risks.

When does a rotating equipment need dynamic balancing in UAE?

New Equipment Installation

When installing a new electric motor rotor, cooling tower fan, blower fans, or pump impeller, manufactured and assembled.

After Repairs or Overhauls

If a rotor has been rewound, rebuilt, repaired, or had parts replaced (e.g., fan blades, impellers, or shafts), dynamic balancing is necessary to correct any introduced imbalance.

Excessive Vibration or Noise

If equipment shows abnormal vibration or noise levels, imbalance could be the cause. This is often observed through increased bearing wear, misalignment, or frequent mechanical failures.

Periodic Maintenance & Condition Monitoring

Over time, material buildup (dust, rust, grease), erosion, or wear can create imbalance in rotating parts. Regular vibration analysis can detect imbalance early and indicate when dynamic balancing is needed.

After a Sudden Impact or Mishandling

If a motor, fan, or rotor has been dropped, hit, or exposed to shock loading, its balance could be affected, requiring rebalancing.

High-Speed or Precision Applications

Equipment operating at high speeds (e.g., turbines, centrifugal compressors, high-speed fans) requires precise balancing to avoid resonance and excessive wear.

What Equipment’s need Dynamic Balancing?

Electric Motor Rotor Balancing

Motor armatures, rotors, and shafts require balancing to minimize vibration, enhance efficiency, and extend bearing life.

Fans & Blowers balancing

Industrial and HVAC fans, cooling tower fans, and ventilation blowers need balancing to prevent excessive noise, reduce energy consumption, and avoid structural damage.

Pumps & Impellers balancing

Centrifugal, axial, and submersible pumps require balancing to ensure smooth fluid flow, prevent shaft misalignment, and avoid excessive bearing wear.

Turbines & Generators Rotor balancing

High-speed equipment like steam and gas turbines, wind turbines, and power generators must be precisely balanced to prevent catastrophic failures.

Gearboxes & Drive Shafts balancing

Rotating shafts, spindles, and couplings in industrial machinery, automotive, and marine applications need balancing to reduce stress and prevent mechanical failures.

Rotating Drums balancing

Rotating drum rollers, conveyer roller etc in various industries require dynamic balancing to maintain efficiency and operational stability.

Various industries that need Dynamic Balancing in UAE?

Dynamic balancing is critical for various industries to ensure smooth operations and avoid costly machine failures. Our clients include:

Oil & Gas Dynamic balancing

Offshore and onshore pump, turbine, and motor balancing.

Marine & Shipping Dynamic balancing

Propeller, generators, marine motors, and engine component balancing.

HVAC & Cooling Systems Dynamic balancing

Balancing of chiller fans and air handling units.

Manufacturing & Heavy Industries Dynamic balancing

Machine spindle, rotor, and conveyor system balancing.

Automotive & Aerospace Dynamic balancing

Engine and drivetrain component balancing.

Power Plants & Utilities dynamic balancing

Generator and turbine balancing for uninterrupted power supply.

Frequency Asked Question for Dynamic Balancing Services in UAE

When selecting a dynamic balancing company, look for proven experience, certified technicians, and advanced equipment capable of handling a wide range of rotating machinery. Daniel Group offers industry-leading expertise, adhering to international standards, and providing precision dynamic balancing services across the UAE to ensure optimal equipment performance and longevity.

A dynamic balancing machine is specialized equipment designed to detect and correct imbalances in rotating components such as rotors, fans, motor shafts, and turbines. By accurately identifying uneven weight distribution, it helps reduce vibrations, prevent excessive wear, improve efficiency, and extend the lifespan of industrial machinery. Daniel Group uses advanced dynamic balancing machines to ensure optimal performance and reliability for all types of rotating equipment.

Dynamic balancing is the process of adjusting the mass distribution of a rotating component to minimize vibration and maximize efficiency. It involves high-precision sensors and corrective techniques to achieve optimal balance.

We offer on-site and in-house dynamic balancing in Dubai, Abu Dhabi, and Sharjah, serving areas like Jebel Ali, Mussafah, Al Quoz, and Hamriyah Free Zone.

If you notice excessive vibration, unusual noise, overheating, or misalignment, your machinery likely requires urgent balancing to prevent further damage.

Industries such as oil & gas, marine, power plants, manufacturing, and HVAC systems rely on dynamic balancing for smooth operations and increased efficiency.

Yes! Our 24/7 emergency dynamic balancing team is available across Dubai, Abu Dhabi, and Sharjah to quickly diagnose and resolve vibration issues.

The duration depends on the size and complexity of the equipment. Our team ensures a quick turnaround, whether in-house or on-site, to minimize disruption to your operations.

Absolutely! Our on-site dynamic balancing services allow us to balance your rotors, shafts, and fans directly at your facility, minimizing downtime.

- Reduces vibration and noise

- Extends equipment lifespan

- Prevents unexpected breakdowns

- Increases operational efficiency and safety

The soft-bearing machine derives its name from the fact that its supports are free to move (soft) in at least one direction, usually horizontally or perpendicularly to the rotor axis. The theory behind this style of balancing is simple: the rotor essentially behaves as if suspended in mid-air while the movements of the rotor are measured with vibration sensors to determine the unbalance of the rotor. The mechanical design of a soft-bearing machine is slightly more complex, but the electronics involved are relatively simple compared to the hard-bearing machines.

Hard-bearing balancing machines have stiff work supports (hard) and rely on vibration to interpret the unbalance in a rotor. This requires a massive, stiff foundation for the machines to be permanently set and calibrated in place by the manufacturer. The theory behind this balancing system is that the rotor is fully constrained and the forces that the rotor puts on the supports are measured. Background vibration from adjacent machines or activity on the work floor can affect balancing results. Commonly, hard-bearing balancing machines are used in manufacturing production operations where a fast cycle time is required.

Simply contact us at sales@danielgroup.ae or call us on +97143476784. We offer customized balancing solutions for industrial, marine, oil & gas, and manufacturing sectors across the UAE.

Other Services

Get in touch

Need An Urgent Repair Or Preventive Motor Service?

We’re just a message away! Trust our experts for top-notch motor services tailored to your needs.