Electric Motor Rewinding Services

Electric Motor Rewinding Services in UAE

HV & LV Specialists expert rewinding solutions for high-voltage (HV) and low-voltage (LV) motors at Daniel Group — ensuring maximum efficiency and extended lifespan across Dubai, Abu Dhabi, Sharjah, and the Northern Emirates.

Electric motor rewinding is the process of replacing the copper windings within a motor's stator or rotor to restore its original performance and efficiency. Rewinding becomes essential when insulation deteriorates, coils burn out, or the motor experiences electrical faults. At Daniel Group, we provide precision HV and LV electric motor rewinding service across the UAE, using advanced techniques and premium materials to minimize downtime and extend equipment lifespan.

Rewinding an electric motor offers several practical and financial advantages over replacing it with a new unit—especially in the UAE’s industrial and commercial sectors. Whether you're maintaining HVAC systems in Dubai, operating heavy-duty machinery in Abu Dhabi, or managing manufacturing setups in Sharjah, motor rewinding is often the smarter choice.

Cost Efficiency

Rewinding is typically 30–50% less expensive than purchasing a new motor, especially for medium to large HP motors. It offers significant savings while restoring full performance.

Faster Turnaround

Procurement and delivery of a new motor can take days or even weeks. Rewinding—especially by local providers like Daniel Group in Dubai Industrial City—can get your motor back online within 24–72 hours.

Preserves Original Specifications

Professional rewinding retains the original design, efficiency class, and insulation system in accordance with IEC 60034-23 guidelines, ensuring the motor performs as intended by the OEM.

Custom Upgrades Possible

During rewinding, insulation systems can be upgraded to higher thermal classes, improving motor life and performance. At Daniel Group, motors originally built with Class ‘F’ insulation are rewound using Class ‘H’ copper wires and insulation.

Eco-Friendly & Sustainable

Rewinding avoids discarding perfectly reusable components like the stator core, rotor, and frame. This reduces waste and supports sustainable maintenance practices.

Avoids Supply Chain Delays

In the UAE, sourcing new motors—especially for imported or obsolete models—can be delayed due to logistics. Rewinding eliminates these supply chain disruptions and downtime risks.

Extends Motor Life

When performed correctly according to AEMT and EASA standards, rewinding restores the motor to like-new condition and significantly extends its operational lifespan.

Critical for Custom Processes

Rewinding is often the most practical and cost-effective solution for large or custom-designed machinery, where finding a like-for-like replacement motor is difficult, expensive, or time-consuming.

While often used interchangeably, electric motor rewinding and motor overhauling are two distinct services, each addressing different maintenance needs.

Electric Motor Rewinding at Daniel Group

What is Motor Rewinding?

Rewinding is a core electrical restoration process where damaged or aged windings—usually in the stator and sometimes the rotor—are removed and replaced. This involves:

- Stripping old coils

- Replacing copper windings

- Upgrading insulation

- Varnishing and curing

- Full electrical testing

Rewinding is typically required when motors fail electrically due to insulation breakdown, phase-to-phase faults, or overloads. It's essential for HV/LV motors, both form-wound and random-wound machines, and is especially critical in UAE sectors such as district cooling, marine, oil & gas, and cement.

Electric Motor Overhauling/Service at Daniel Group

What is Motor Overhauling?

Motor overhauling or servicing is a comprehensive mechanical and electrical process focused on restoring the entire motor to optimal working condition. It includes:

- Complete disassembly

- Bearing replacement

- Shaft alignment

- Housing repairs

- Dynamic balancing

- Inspection and cleaning of stator/rotor

- Electrical testing (without rewinding unless necessary)

Overhauling is ideal for preventive maintenance or when motors show signs of mechanical wear, vibration, or decreased performance—common in Dubai’s heavy-duty industrial environments.

In short:

- Rewinding → Replace core electrical windings to fix insulation or coil failures.

- Overhauling → Restore mechanical and basic electrical performance.

Electric motor rewinding is essential for restoring motor efficiency and reliability, particularly in high-demand sectors across the UAE such as oil & gas, manufacturing, marine, utilities, and district cooling. Below are the key components that often require rewinding, based on industry standards like IEC, IEEE, AEMT, and EASA guidelines.

Stator Windings

The stator is the heart of the motor’s electromagnetic system. Over time, its windings can deteriorate due to heat, moisture, or voltage spikes. Rewinding the stator with upgraded insulation (Class F or H) restores full performance while ensuring thermal and electrical protection, especially for both LV and HV motors.

Rotor Windings

Common in wound rotor induction motors, rotor windings often fail due to wear, imbalance, or thermal stress. Rewinding these helps eliminate torque fluctuations, noise, and vibration, improving motor stability and efficiency for heavy-duty applications in the UAE.

Field Coils & Armature Windings (DC Motors)

DC motors used in cranes, pumps, and industrial machinery frequently require rewinding of their field coils and armatures. This restores torque delivery and consistent speed control—key for precision-driven applications.

Excitation Windings (Generators & Alternators)

Excitation windings are crucial for controlling output voltage in synchronous generators and alternators. Thermal fatigue, insulation failure, or overloads can impair excitation performance. Precision rewinding ensures stable excitation current and improved voltage regulation, especially in power-critical industries like utilities and marine power systems.

The UAE’s extreme climate—soaring temperatures, humidity, and fine desert dust—poses serious challenges for both electric motors and generator alternators. Whether you're in Dubai's industrial zones, Sharjah’s port areas, or Abu Dhabi’s oil fields, your rotating equipment is constantly exposed to environmental stress, which shortens service life and increases the need for professional rewinding services.

Electric motor rewinding is the process of replacing the copper windings within a motor's stator or rotor to restore its original performance and efficiency. Rewinding becomes essential when insulation deteriorates, coils burn out, or the motor experiences electrical faults. At Daniel Group, we provide precision HV and LV motor rewinding services across the UAE, using advanced techniques and premium materials to minimize downtime and extend equipment lifespan.

Rewinding an electric motor offers several practical and financial advantages over replacing it with a new unit—especially in the UAE’s industrial and commercial sectors. Whether you're maintaining HVAC systems in Dubai, operating heavy-duty machinery in Abu Dhabi, or managing manufacturing setups in Sharjah, motor rewinding is often the smarter choice.

Cost Efficiency

Rewinding is typically 30–50% less expensive than purchasing a new motor, especially for medium to large HP motors. It offers significant savings while restoring full performance.

Faster Turnaround

Procurement and delivery of a new motor can take days or even weeks. Rewinding—especially by local providers like Daniel Group in Dubai Industrial City—can get your motor back online within 24–72 hours.

Preserves Original Specifications

Professional rewinding retains the original design, efficiency class, and insulation system in accordance with IEC 60034-23 guidelines, ensuring the motor performs as intended by the OEM.

Custom Upgrades Possible

During rewinding, insulation systems can be upgraded to higher thermal classes, improving motor life and performance. At Daniel Group, motors originally built with Class ‘F’ insulation are rewound using Class ‘H’ copper wires and insulation.

Eco-Friendly & Sustainable

Rewinding avoids discarding perfectly reusable components like the stator core, rotor, and frame. This reduces waste and supports sustainable maintenance practices.

Avoids Supply Chain Delays

In the UAE, sourcing new motors—especially for imported or obsolete models—can be delayed due to logistics. Rewinding eliminates these supply chain disruptions and downtime risks.

Extends Motor Life

When performed correctly according to AEMT and EASA standards, rewinding restores the motor to like-new condition and significantly extends its operational lifespan.

Critical for Custom Processes

Rewinding is often the most practical and cost-effective solution for large or custom-designed machinery, where finding a like-for-like replacement motor is difficult, expensive, or time-consuming.

While often used interchangeably, electric motor rewinding and motor overhauling are two distinct services, each addressing different maintenance needs.

Electric Motor Rewinding at Daniel Group

What is Motor Rewinding?

Rewinding is a core electrical restoration process where damaged or aged windings—usually in the stator and sometimes the rotor—are removed and replaced. This involves:

- Stripping old coils

- Replacing copper windings

- Upgrading insulation

- Varnishing and curing

- Full electrical testing

Rewinding is typically required when motors fail electrically due to insulation breakdown, phase-to-phase faults, or overloads. It's essential for HV/LV motors, both form-wound and random-wound machines, and is especially critical in UAE sectors such as district cooling, marine, oil & gas, and cement.

Electric Motor Overhauling/Service at Daniel Group

What is Motor Overhauling?

Motor overhauling or servicing is a comprehensive mechanical and electrical process focused on restoring the entire motor to optimal working condition. It includes:

- Complete disassembly

- Bearing replacement

- Shaft alignment

- Housing repairs

- Dynamic balancing

- Inspection and cleaning of stator/rotor

- Electrical testing (without rewinding unless necessary)

Overhauling is ideal for preventive maintenance or when motors show signs of mechanical wear, vibration, or decreased performance—common in Dubai’s heavy-duty industrial environments.

In short:

- Rewinding → Replace core electrical windings to fix insulation or coil failures.

- Overhauling → Restore mechanical and basic electrical performance.

Electric motor rewinding is essential for restoring motor efficiency and reliability, particularly in high-demand sectors across the UAE such as oil & gas, manufacturing, marine, utilities, and district cooling. Below are the key components that often require rewinding, based on industry standards like IEC, IEEE, AEMT, and EASA guidelines.

Stator Windings

The stator is the heart of the motor’s electromagnetic system. Over time, its windings can deteriorate due to heat, moisture, or voltage spikes. Rewinding the stator with upgraded insulation (Class F or H) restores full performance while ensuring thermal and electrical protection, especially for both LV and HV motors.

Rotor Windings

Common in wound rotor induction motors, rotor windings often fail due to wear, imbalance, or thermal stress. Rewinding these helps eliminate torque fluctuations, noise, and vibration, improving motor stability and efficiency for heavy-duty applications in the UAE.

Field Coils & Armature Windings (DC Motors)

DC motors used in cranes, pumps, and industrial machinery frequently require rewinding of their field coils and armatures. This restores torque delivery and consistent speed control—key for precision-driven applications.

Excitation Windings (Generators & Alternators)

Excitation windings are crucial for controlling output voltage in synchronous generators and alternators. Thermal fatigue, insulation failure, or overloads can impair excitation performance. Precision rewinding ensures stable excitation current and improved voltage regulation, especially in power-critical industries like utilities and marine power systems.

The UAE’s extreme climate—soaring temperatures, humidity, and fine desert dust—poses serious challenges for both electric motors and generator alternators. Whether you're in Dubai's industrial zones, Sharjah’s port areas, or Abu Dhabi’s oil fields, your rotating equipment is constantly exposed to environmental stress, which shortens service life and increases the need for professional rewinding services.

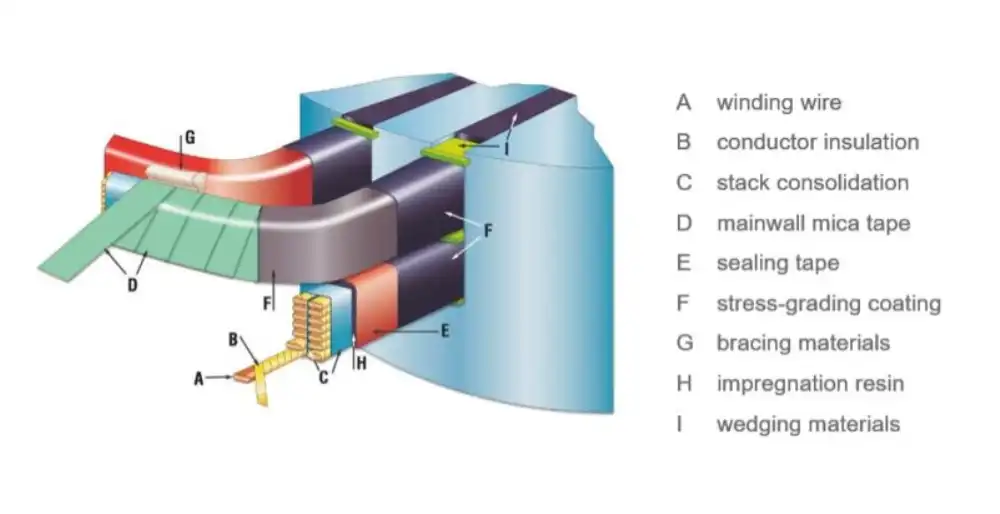

Motor Winding Insulation at Daniel Group

Form-Wound Coil Windings

Used in high-voltage motors and large industrial machines, form-wound coils are pre-shaped with consistent geometry before being inserted into stator slots. These windings offer high dielectric strength, better mechanical stability, and improved thermal management.

Common in motors above 3.3kV, synchronous motors, and generator stators. Ideal for:

- Power generation plants

- Marine propulsion systems

- District cooling and oil & gas installations

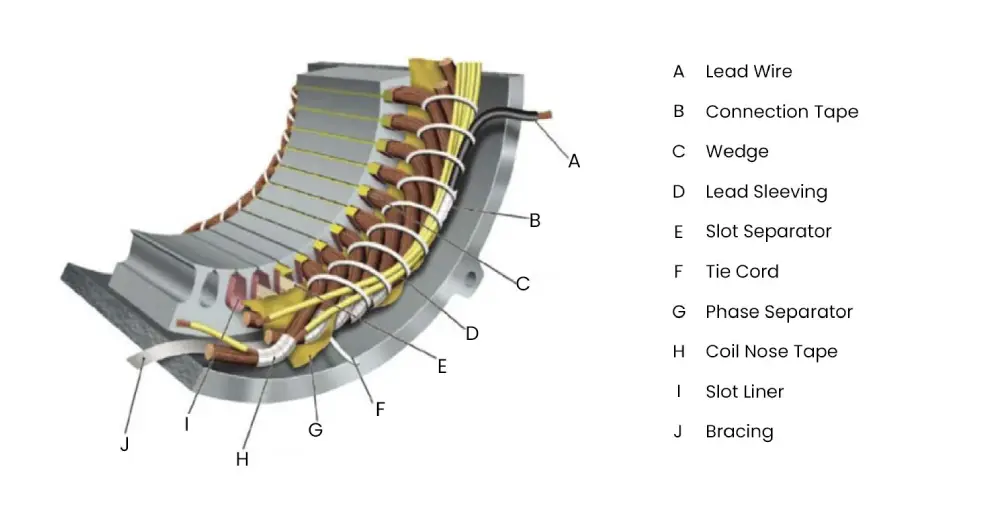

Random-Wound Coil Windings

Random-wound coils are widely used in low-voltage AC motors (typically below 690V). These windings are laid into the stator slots without a defined position, making them suitable for high-volume production and small-to-medium motors.

Preferred for:- Pumps, compressors, HVAC motors

- Industrial conveyors, small machines

- Portable generator motors

Advantages: Cost-effective, faster to manufacture, and easy to rewind.

Electric Motor Rewinding Process

Rewinding an electric motor is a meticulous procedure that restores its efficiency and extends its operational life. Here’s an overview of the key steps involved:

Electric Motor Assessment & Data Collection

- Initial Inspection: Once the motor is received, it is thoroughly inspected by the Motor Rewinding Department.

- Documentation: All winding configurations, wire sizes, and coil turns are recorded to ensure accurate replication—exactly as per the OEM specifications.

Removal of Old Windings

- Burnout Process: Place the stator in a controlled oven to remove varnish and loosen old windings.

- Core Testing: Perform pre- and post-burn core tests to ensure the iron core remains intact.

Stator Preparation

- Cleaning: Use non-abrasive methods to clean stator slots without damaging the core laminates.

- Slot Inspection: Check for sharp edges and apply appropriate insulation materials to prepare for new windings.

Coil Manufacturing & Insertion

- Coil Manufacturing: Manufacture new coils based on collected data, ensuring correct wire gauge and insulation.

- Insertion: Carefully insert coils into stator slots, protecting insulation integrity throughout the process.

Connection & Insulation

- Lead Connections: Make winding connections according to the motor's wiring diagram, ensuring proper phase alignment.

- Insulation Application: Apply insulating materials between coil layers and at slot exits to maintain or upgrade to Class H insulation.

Varnishing & Curing

- Varnish Application: Impregnate the stator with insulating varnish to secure windings and enhance dielectric strength.

- Curing: Bake the stator at specified temperatures to cure the varnish and solidify the insulation system.

Reassembly & Final Testing

- Motor Reassembly: Reinstall all components, including bearings and end bells, ensuring proper alignment.

- Performance Testing: Conduct no-load and load tests to verify motor performance meets original specifications.

Various industries that need electric motor rewinding in UAE?

Frequency Asked Question Electric Motor Rewinding Service in the UAE

At Daniel Group, every electric motor rewinding Dubai project follows strict OEM standards. We use advanced diagnostic tools, including surge comparison and insulation resistance testing, ensuring motors operate at peak efficiency with uncompromised safety.

Electric motor rewinding is the process of restoring your motor’s coils to like-new condition, improving efficiency and performance. In the UAE’s harsh climate, rewinding is essential to combat heat, humidity, and sand exposure—extending motor lifespan in industries from oil & gas to HVAC.

Daniel Group is the UAE’s leading motor rewinding expert, trusted by marine, industrial, and power clients. With premium materials, ISO procedures, and rapid turnaround, we deliver unmatched motor repair and rewinding services across all Emirates.

Yes. We specialize in rewinding both LV and HV motors, including 415V, 3.3kV, 6.6kV, and even 11kV units—serving industries across Dubai, Abu Dhabi, and Sharjah.

In most cases, rewinding is up to 70% more cost-effective than buying a new motor. Our clients across Dubai and Sharjah trust us for OEM-grade rewinding that restores full performance—especially for high-value or discontinued motors.

Depending on size and condition, rewinding can take anywhere from 2 to 7 days. We offer urgent delivery options for critical applications—often over weekends or holidays.

Yes. We follow OEM-aligned rewinding practices and ensure full testing before delivery. We also support OEM-spec rewinding based on customer requirements, with all our windings backed by a 1-year warranty.

If your motor shows symptoms like overheating, unusual noise, or a drop in performance—but the core components (like rotor and stator) are intact—rewinding is usually the smarter, more economical choice.

Yes. We offer pickup and delivery for motors in Dubai, Abu Dhabi, Sharjah, Ajman, and other Emirates. Just contact our sales team.

Yes—we handle generator alternator rewinding, excitation system restoration, and field coil repair. We serve generator rental companies, construction firms, and backup power facilities across the UAE.

With proper maintenance, a Daniel Group–rewound motor performs comparably to a new motor—and often lasts just as long.

Not all motors are suitable for rewinding. Some may have severe core or mechanical damage. A professional assessment will determine the feasibility.

Other Services

Get in touch

Need An Urgent Repair Or Preventive Motor Service?

We’re just a message away! Trust our experts for top-notch motor services tailored to your needs.