Author: Daniel Group

July 23rd, 2025

Electric motors serve as the driving force behind many industrial processes, like HVAC, utilities, marine, and manufacturing industries. Despite being extremely dominant, it is often left vulnerable to costly unplanned downtime.

This is the point where preventive maintenance emerges as a critical differentiator. In simple words electric motor preventive maintenance ensures consistent performance and extended lifespan by anticipating any possible failure in advance. It can successfully cut downtime, boost the overall productivity while also helping in reducing operational costs.

Skipping the maintenance part can land you in some severe problems. For instance unnoticed misalignments, premature wearouts, and degraded insulation can result in heat accumulation, vibration problems, and total motor failure. Unplanned shutdowns can cause expensive emergency repairs or replacements, stop output, and extend project timeframes. In addition to monetary loss, safety risk also increases in many cases.

Before diving into the profound details of preventive maintenance, let’s learn what it is exactly. Preventive maintenance means to regularly check, test or service electric motors at scheduled timings. In contrast to predictive maintenance which utilizes data of advanced analytics to predict any problem, preventive maintenance follows a set routine and focuses on common wear and tear patterns. Some of the basic tasks of preventive maintenance include:

Through all such protective tests and measures, preventive maintenance successfully extends the lifecycle of the motor and makes it run safely and efficiently.

Preventive care is not a one-size-fits-all approach, as it depends on multiple motor variations. Hence, these packages must be customized depending upon the motor’s size, voltage class (HV or LV), duty cycle, the environment it operates in (Eg, humid, dusty or marine ) and the load’s condition. Let’s learn about the various reliable industrial methods that contribute to creating a durable and steadfast electric motor system:

It is often the first step of preventive maintenance where the technicians inspect the exterior of the motor for any visible signs of trouble. They examine :

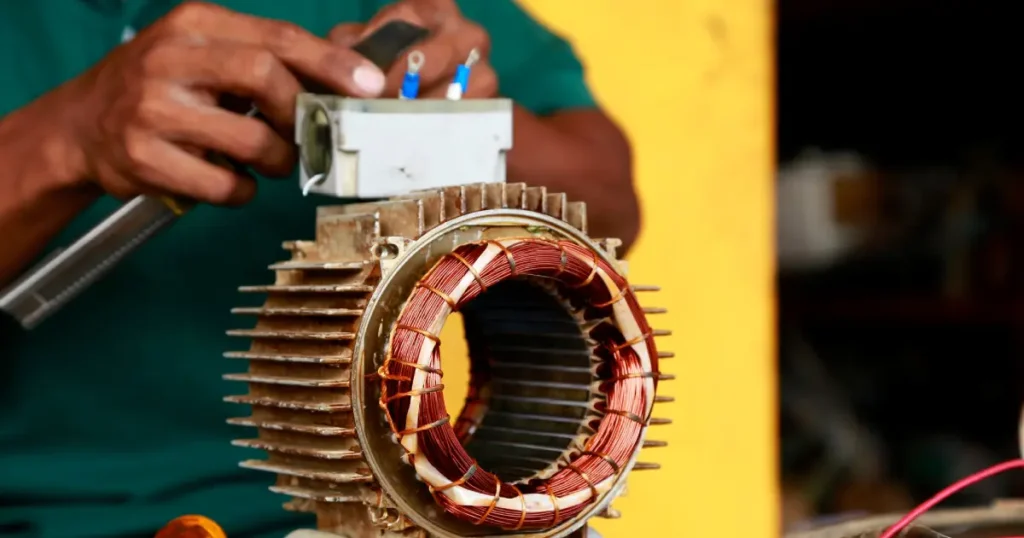

Unbalanced motors lead to the production of excessive vibrations which ultimately cause structural stress and bearing failure at an early stage. Hence, it is certainly important to achieve uniform rotations that involve dynamic balancing. This technique involves measuring rotor imbalance and redistributing mass, which leads to reduced vibration levels with extended bearing life and enhanced operational stability. The method is highly effective for both high speed or high load applications.

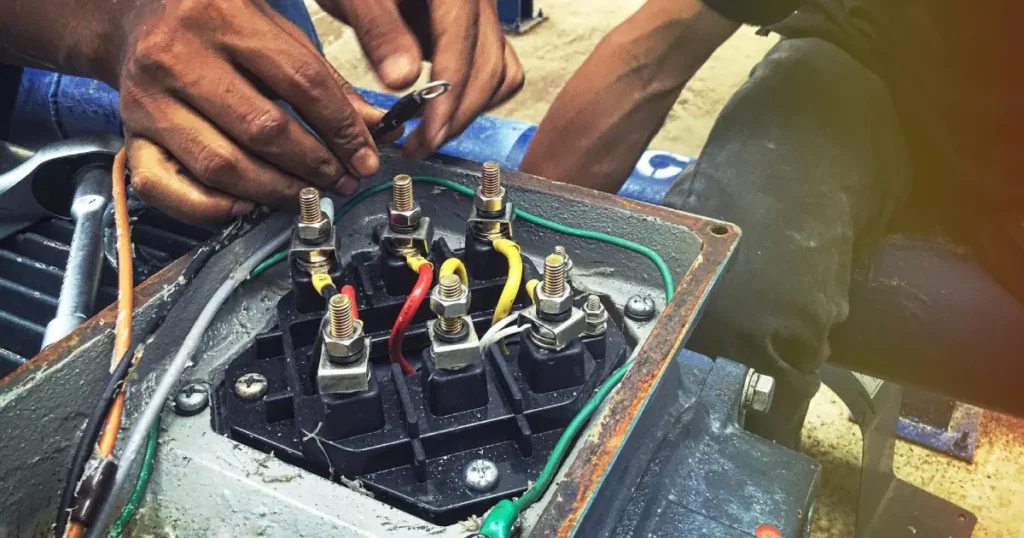

Electrical testing don’t just rely upon basic testing, it involves a series of tests which include:

| Insulation Resistance testing | Surge Comparison Testing | Polarization Index Measurement | PD and HV testing |

| The testing is done through a megohmmeter, which helps identify any insulation wear in the motor. | This testing handles the windings and detects any inter-turn short circuits in it. | The index here assesses the quality of insulation in motors. Over time these tests help diagnose the following problems in motor windings:Internal faultsThermal degradationMoisture absorption | This testing efficiently identifies early degradation in the insulation of the motor. |

Motor windings over some period of time tend to degrade as a result of exposure to heat, overloading or environmental conditions. Hence, the rewinding technique is practiced, which includes swapping the old coils with new ones. After this these new coils are protected with class–H insulating varnish. This varnishing process saves the coil from any electrical and mechanical stress.

Stress buildup is a common and regular issue in electric motors. Hence, to prevent such complications, proper alignment of the motor shaft and rotor assembly is important to maintain. Under preventive maintenance, the inspection of the shaft and rotor includes:

Note: Shaft damage, if left ignored, can lead to serious problems like stressing the connected systems, leading to deteriorated motor performance.

Bearings are believed to be the most failure prone component of a motor. It’s important that these parts should be lubricated regularly to minimize any friction, reduce heat buildup, and prevent bearing seizure. The maintenance team under this process does the following :

Timings of preventive maintenance are equally essential to surge the overall efficiency of the motor. Further, are the key indicators and intervals when the servicing of the motor should be scheduled:

No doubt, motor preventive maintenance is essential, but choosing the right service provider matters even more. Selecting a skilled and expert service provider guarantees the success of the maintenance program. Daniel Group, with extensive experience in preventive maintenance of the electric motor, delivers excellent services that align with the global benchmarks of ISO, IEC and IEEE standards. They are proficient in the process of :

Daniel Group maintains a skilled team fortified with precision equipment and helps you with faster turnaround times, customized maintenance strategies, and consistent quality control, ultimately extending your equipment’s lifespan.

Smart monitoring has replaced manual tests as the backbone of modern maintenance. This includes real-time monitoring of variables like temperature, vibration, and energy usage through smart devices like sensors and Internet of Things. These insights aid in proactive maintenance scheduling, performance improvement, and failure prediction.

People often assume maintenance to be useless or too expensive for small scale industries. But in reality, the reverse is true. Small industries with its low budget find it difficult to deal with extensive repairs, hence routine motor maintenance often fits more nicely in budget.

Another myth includes that new motors don’t require maintenance; but the truth is that you can’t evaluate performance decline over time without baseline data.

Preventive maintenance is a long-term strategy that increases the reliability and sustainability of your electric motor. It reduces risks and protects your high-stakes industries under every circumstance. Don’t wait for that breakdown to surprise you and invest in your assets today! Reach out to Daniel Group for expert solutions to all your electric motor needs.