Author: Daniel Group

October 30th, 2025

Reliable power generation is at the heart of every marine operation. When a vessel’s alternator begins to lose efficiency or fails unexpectedly, Marine Alternator Rewinding becomes the most effective solution to restore performance and extend lifespan. At Daniel Group, each rewinding project—such as the intricate 1615 KVA marine alternator—is executed with unmatched precision, technical expertise, and compliance with international marine standards.

Our approach to alternator rewinding service is built on engineering excellence, advanced diagnostics, and strict quality control. Whether for scheduled maintenance or emergency alternator repair, every process step ensures efficiency, reliability, and seamless operation at sea.

Marine alternators operate in some of the harshest conditions—high humidity, vibration, and constant salt exposure. These elements can degrade insulation, loosen windings, and compromise efficiency. Precision in Marine Alternator Rewinding is therefore vital, as even the smallest misalignment in the alternator winding can lead to electrical imbalance or system failure.

Choosing a specialized alternator rewinding service means relying on experts who understand that there are no room for errors. At Daniel Group, our technicians follow detailed inspection and rewinding protocols to ensure each alternator performs flawlessly under heavy-duty maritime loads. This focus on precision engineering not only restores function but also enhances long-term reliability and energy efficiency.

Every successful alternator rewinding service begins with a comprehensive assessment. Our engineers conduct detailed mechanical and electrical inspections to determine the root cause of failure—be it overheating, moisture ingress, or mechanical imbalance. Using advanced diagnostic tools, we measure insulation resistance, continuity, and voltage levels to pinpoint issues within the stator or rotor assembly.

For urgent cases, the team is fully equipped for emergency alternator repair, ensuring minimal downtime for vessels in port or dock. The initial inspection phase establishes a clear repair roadmap, allowing precise rewinding and reassembly tailored to the alternator’s design and capacity.

Once diagnostics are complete, the alternator undergoes careful disassembly. The stator and rotor are separated, bearings are removed, and worn components are logged for replacement. This process requires meticulous handling to prevent core or lamination damage.

The old alternator winding is stripped using specialized tools, followed by thorough cleaning to remove carbon deposits, salt, and oil residues. Our technicians use marine-grade solvents that preserve metal integrity and ensure a clean, corrosion-free surface. The alternator core is then inspected under magnification for cracks or distortions before proceeding to the rewinding stage.

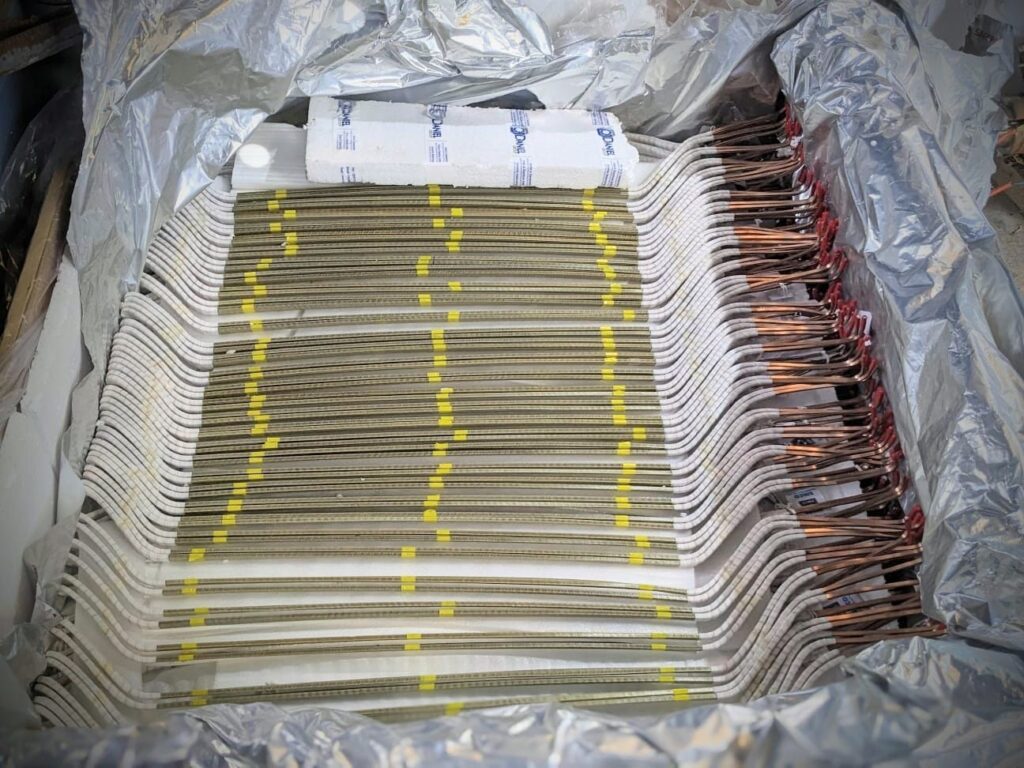

In this critical stage, new alternator winding coils are prepared using high-conductivity copper wire with class H insulation capable of withstanding up to 180°C. The winding configuration is replicated according to the manufacturer’s specifications or custom-engineered for optimized performance.

Each coil is meticulously placed into the stator slots and secured with slot wedges and insulation liners. Varnish Impregnation is performed to ensure deep varnish penetration, providing maximum moisture and vibration resistance. This process is central to the durability of any Marine Alternator Rewinding project.

Certain Generators come with Form wound coils. As the name suggests these are made with a pre-shaped (pre-formed) coil geometry, instead of being wound directly in the stator slots like low-voltage motors. At Daniel Group these form wound coils are prepared with utmost precision and test to the highest standards.

The combination of premium materials, calibrated winding tension, and uniform layering guarantees stable electrical output and enhanced alternator lifespan.

After winding, the alternator is varnished to insulate and protect the coils. The stator is immersed in high-grade H class varnish and subjected to an impregnation process to eliminate air pockets and strengthen coil bonding.

Once coated, the assembly is oven-cured at controlled temperatures to harden the insulation, ensuring superior dielectric strength. This step also prevents corrosion and electrical leakage during operation. Daniel Group’s alternator rewinding service employs marine-specific varnishing materials that can withstand prolonged exposure to salt-laden environments.

The varnishing and curing process not only enhances electrical insulation but also improves mechanical rigidity, crucial for ships operating under constant vibration.

Once curing is complete, reassembly begins with high-precision alignment of the rotor and stator. Bearings are replaced or re-lubricated, and all mechanical tolerances are verified. During this phase, dynamic balancing is carried out using advanced balancing machines to eliminate vibration and ensure stable rotation under load.

The alternator then undergoes multiple tests—insulation resistance, continuity, and load simulation—to verify performance accuracy. For vessels requiring urgent restoration, Daniel Group’s emergency alternator repair service ensures that fully tested and balanced alternators are reinstalled within the shortest possible timeframe, minimising operational delays.

After mechanical assembly, the alternator is subjected to rigorous testing under simulated marine operating conditions. Parameters such as phase balance, voltage stability, and frequency output are closely monitored.

Our Marine Alternator Rewinding projects undergo a full load test to confirm consistent performance across all phases. Each alternator is validated against OEM specifications, and a complete inspection report is generated for transparency and compliance.

This attention to detail ensures that every alternator rewinding service not only restores functionality but also enhances reliability and efficiency in demanding environments.

Marine alternators that have undergone professional rewinding often outperform their original lifespan when properly maintained. Regular vibration analysis, insulation resistance checks, and scheduled inspections can significantly reduce the risk of future breakdowns.

Daniel Group offers tailored maintenance plans and technical support for all alternator rewinding service requests, ensuring long-term dependability. Our engineering teams also assist with load balancing, alignment verification, and operational diagnostics to prevent early wear and maintain optimal power output at sea.

When it comes to high-capacity alternators like the 1615 KVA unit, precision, expertise, and reliability matter most. Daniel Group combines decades of experience with advanced workshop capabilities to deliver superior Marine Alternator Rewinding services across the UAE.

Our facility is equipped for large-scale alternator handling, alternator winding, dynamic balancing, and emergency alternator repair, ensuring minimal downtime for clients in the marine and offshore industries. Each project follows international standards such as IEC 60034 and ISO 9001, backed by complete traceability and testing documentation.

By partnering with Daniel Group, clients gain access to a trusted electromechanical solutions provider capable of managing complex marine alternator repairs with accuracy and speed.

If your alternator shows reduced performance, overheating, or inconsistent output, professional intervention is the key to avoiding costly failures. Daniel Group delivers comprehensive alternator rewinding service and full-scale Marine Alternator Rewinding solutions tailored for maritime applications.

Our team of certified technicians and marine engineers ensures your alternator is rebuilt for efficiency, durability, and compliance with marine operational standards. Visit Daniel Group to explore our complete range of electromechanical services or request a consultation with our specialists today.